The Basics of Rotational Grazing

Determining the best stocking and grazing system for your operation can be overwhelming. It can be difficult to try to combine various new recommendations with the existing traditions already engrained in your practice. How can you be certain that the method you choose is correct?

Grazing management can never be reduced down to a system that is exactly right, for every operation, at all times. In short, “No one stocking method is best!” said Dr. Benjamin Tracy.

Dr. Tracy is a rotational grazing expert, with over 18 years of experience at Virginia Tech University, where his research is rooted in managing plant diversity in forage-livestock systems to improve their productivity.

When speaking with Dr. Tracy, it became apparent that he is passionate about the fact that grazing management is extremely subjective. While his research is focused on rotational grazing, he said that each style of grazing management has its own objective, and no single method can be the correct choice for every operation. No matter the grazing system used, the most important factor to consider is developing an intentional, structured management system.

Rotational grazing can be a great system to increase the production of your forage base, give greater flexibility in your forage used (allowing for overlap between warm and cool season grasses), increased drought tolerance, and extending your grazing season.

According to a 2020 study conducted by South Dakota State University, producers who used an intensive grazing season saw an average grazing season of 235 days. This is compared to the average grazing season of 182 days under continuous grazing, and 197 days under basic rotational grazing systems.

According to a study done by the USDA Economic Research Service, they found that in 2018, 40% of cow-calf operations had adopted some form of rotational grazing. The difference between basic and intensive rotational grazing is determined based on the days each paddock is grazed. Intensive rotational grazing uses an average grazing period of 14 days or less per paddock. Basic rotational grazing utilizes 14 days or more per paddock.

When utilizing a rotational grazing management system, the way you stock your animals greatly depends on your land, according to Dr. Tracy. When determining the best rotational stocking structure for your operation, he recommends three basic initial calculations.

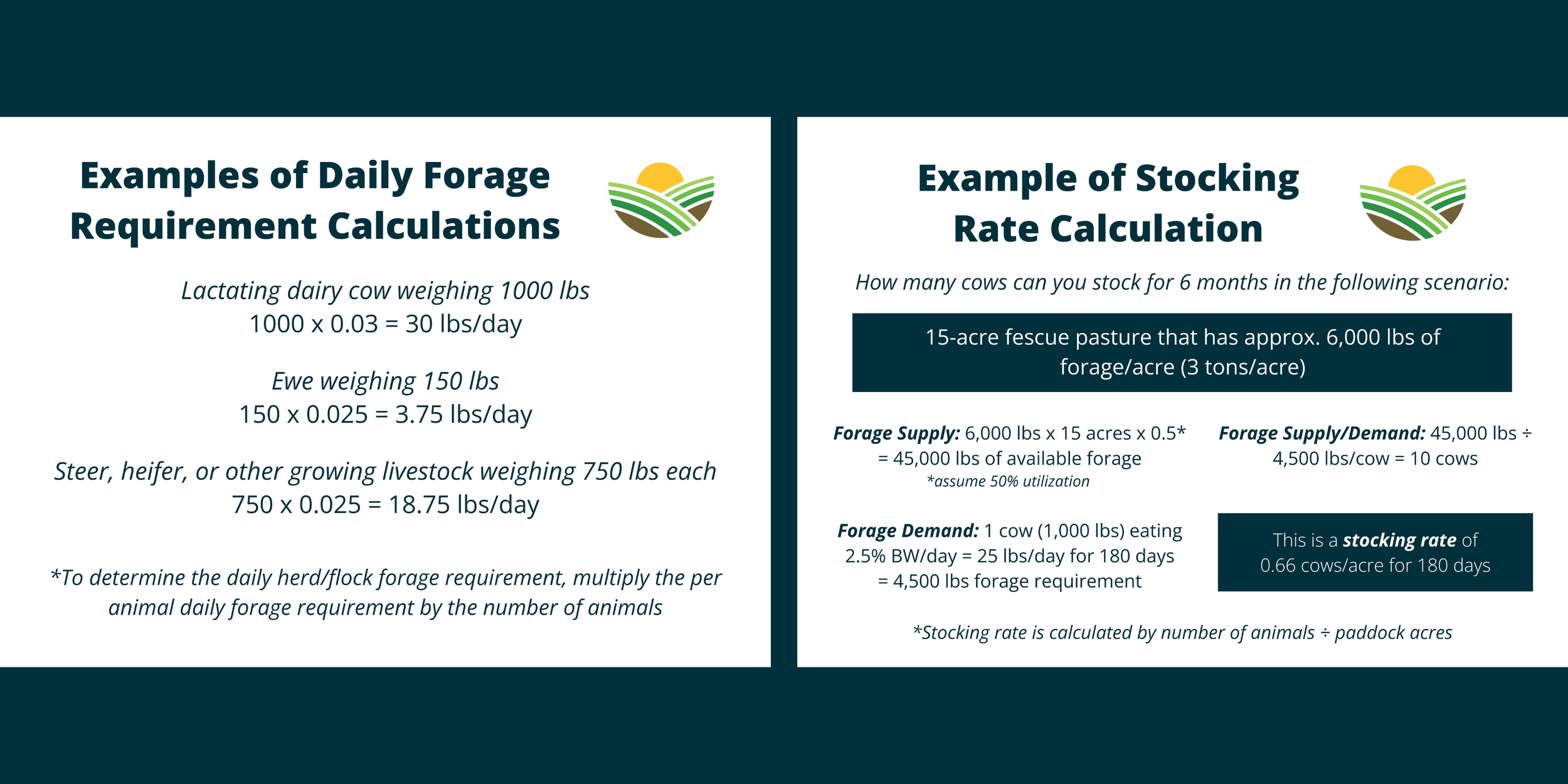

First is to estimate the forage supply, either by direct calculation, or extrapolated from available databases (such as from your state’s Extension service). On average, a typical fescue pasture in the Southeast will produce between 2-4 tons of forage per acre in a typical year. Next is to estimate your forage supply and demand, or stocking rate. Most livestock need to eat about 2.5-3% of their body weight each day.

The last step in designing your rotational grazing system is to estimate the number of paddocks needed. That can be done by determining the average time you want to graze each paddock (basic or intensive grazing), while allowing for 30-32 days of rest during the longest rotation. It is a good rule of thumb to graze each paddock to approximately 3-4 inches, while moving into a paddock that has at least 12 inches of growth.

One thing that Dr. Tracy was clear on, is that rotational grazing is not an exact science. “You have to match your moves with how your forage is growing and how your animals are grazing,” said Dr. Tracy.

Whether basic or intensive rotation, or some other system entirely, is right for you, the most important practice to implement is a dedicated management system for your operation. If you need information on how to get started, NatGLC maintains a grazing resources library, stocked with free, researched-backed resources. Additionally, your local state Extension service is a great place to access state-specific data that could be helpful in calculating your forage supply and stocking rate.